Get creative in your jewelry studio! These four rings were made in a day using silver bands and stacking rings combined with pattern sheet, links, rivets and other fun findings!

Here at Halstead, we sell a wide variety of finger rings, from stacking and midi rings to basic ring bands and more. Step outside of the box with me to create memorable pieces using links, pattern sheet and other fun jewelry making supplies. The four rings shown below are simple to make and can all be finished in a day. Three require soldering while one uses cold connections.

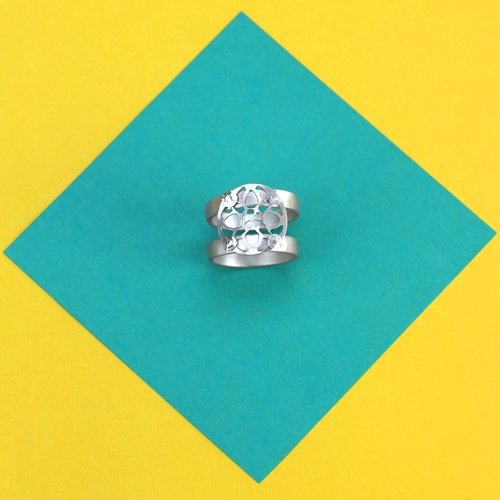

Riveted Quad Ring (skills: drilling, riveting & finishing)

Items used:

- 4 = Sterling silver 1/4in rivets

- 2= 4mm sterling silver ring bands (Item # SR427)

- 1 = 15.7mm sterling silver round quad link (Item # SA204)

I chose two 4mm-wide rings for this design. The rivets that I used were wide and so I needed the surface space to drill 2mm holes. The width of the two bands kept the piece nice and sturdy when it was finished.

To flatten the rivet inside of the ring I chose a small punch and alternated hammering it on either side of the ring band.

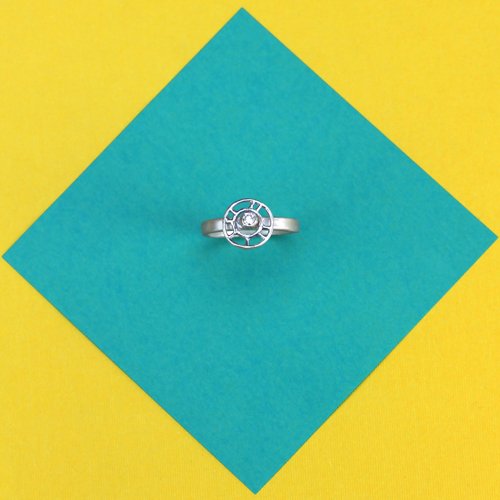

CZ Nestled in a Satin Ring Band (skills: piercing, soldering, filing, finishing, setting)

Items used:

- 1 = 4mm CZ (Item # CZ40LG)

- 1 = 4mm sterling silver tube bezel (Item # S5024)

- 1 = 2mm sterling silver ring band (Item # SR227S)

Mark the width of the tube bezel on the ring band. Use a jeweler's saw to cut the band straight across on those two lines to prevent unnecessary filing which jewelry cutters may cause.

Using flat & round needle files, shape the ring band so it fits flush around the tube bezel.

Structured Circle Link with CZ (skills: soldering, finishing, setting)

Items used:

- 1 = 3mm CZ (Item # CZ30)

- 1 = 3mm sterling silver tube bezel (Item # S5023)

- 1 = 3mm sterling silver satin ring band (Item # SR3328)

- 1 = 10.8mm sterling silver organic link

Solder this all at one time using medium solder. I dropped one piece in the middle of the tube bezel and then one tiny piece between the outside of the tube bezel and the structured circle on each side.

Cleaning this one was a little trickier than the others since I wanted to just clean the circle without damaging the satin finish on the ring band. To do this, I used a hard horsehair brush, followed by a medium goat/horse hairbrush and then polish on a soft goat hairbrush.

Wood Grain Stacking Ring (skills: piercing, filing, patina, finishing)

Items used:

- 1 = 1.4mm sterling silver bar stacking ring (Item # SR5747)

- 1 1/2in = 24ga pattern sheet

With the stacking ring higher on the top of the ring than the pattern sheet, I chose to solder each side separately. I used hard solder on the first join then medium solder on the second one.

After dipping it in Liver of Sulfur, I used 3M radial brushes by skimming them along the top the opposite direction of the wood grain so the brush tips would not be able to reach the imprints. I followed that step with polish on a flat felt wheel to achieve a nice shine.

Watch the Videos!

Watch in the video below as I show you how to solder rings. I add tips to soldering pattern wires, too.

In this video, I'll show you how to solder tube bezels onto finger ring bands.

You may also be interested in these other Halstead articles. Subscribe to receive weekly releases!

Popular Jewelry Trends: Rings Galore!

Soldering Half Round Wire & Pattern Wire for Rings

Granular Stacking Rings Tutorial

Got questions? Email our studio coordinator Erica Stice at [email protected]. We’d love to hear from you. Sorry, studio support is not available by phone. Emails only, please.

Q&A

Q: With utmost sincerity, I’ll say, lovely piece @Erica Stice. Thank you. With all due respect I must ask, is there possibly another polishing tool that will work for your Structured Circle Link project? The horsehair brushes your recommending to @Halsteadbead readers are made from horse remains rendered at slaughterhouses. Last Friday, July 12, 2017, the Appropriations Committee of the U.S. House of Representatives voted to greenlight the reopening of horse slaughter plants in the United States. As a lifelong equestrian who’s worked hard to save these animals her entire life, I implore you to reconsider your polishing options. - Jenn W.

A: Hi Jenn, Thank you for your comment. I understand your concerns but thankfully the company that produces these bristle brushes has been in business for over 100 years and they only remove animal hair and fur from live animals. Their process of removing the hair and fur is done in an ethical way that does not harm the animal in any way and has been in practice for thousands of years. I hope that alleviates your concerns.