This blog will talk about the various ways to finish and polish your jewelry. We’ll talk tumblers, bench-top polishers, and various attachments for your flex shaft.

This blog will be your go-to for jewelry finishing and polishing information! We’ll discuss some of the most popular tools used, like tumblers and bench-top polishing machines, different types of sandpapers and polishing papers, and attachments for your flex shaft. You’ll want to bookmark this one to refer back to! Be sure to shop at Halstead to buy silver for jewelry making.

First we’re going to talk about a few common finishes you will encounter. These can be on manufactured jewelry pieces and components or on handmade pieces.

|

Polished or Brite This is a shiny, mirror-like finish. It takes a lot of work and steps to achieve this finish by hand. |

|

Satin or Matte These terms are often used interchangeably and refer to metal that is dully polished with a diffused glow. |

|

Brushed This refers to tiny wire-brushed mark so n the surface. The marks are usually only in one direction. |

|

Stardust or Sandblast This effect is grainy and sparkly. You will see it referred to as ‘stardust’ for manufactured pieces. If you’re creating a similar finish yourself, you would use a sandblasting machine. It shoots an abrasive medium, like sand, at high pressure at your piece, creating a dimpled surface. |

Sanding and Finishing Papers

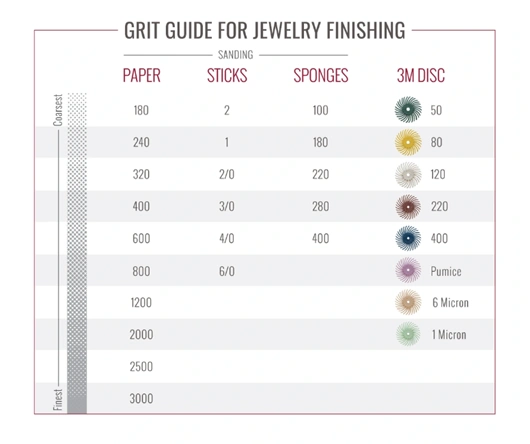

Sandpapers and finishing papers are great ways to finish and polish your jewelry. They come in a range of grits and microns (measures of how coarse or fine they are) so can be used for a wide variety of outcomes. In general, you will want to start with the coarser papers and work your way up to the finer sandpapers, finishing off with polishing papers. Good technique for using sandpapers involves sanding in one direction with the first grit. When you move on to the next grit, you’ll sand in the opposite direction until all marks from the first paper are gone.

Sandpaper

Sandpaper is often part of your first finishing and polishing steps. It’s measured in ‘grits,’ with he higher the number being finer. They’re made with aluminum oxide or silicon carbide particles bonded to paper. Sandpaper is part of initial finishing steps because they can be quite coarse (80 grit) and take away a LOT of material. Additionally, the particles are not uniform, which means they can leave deeper scratches in some areas on your piece.

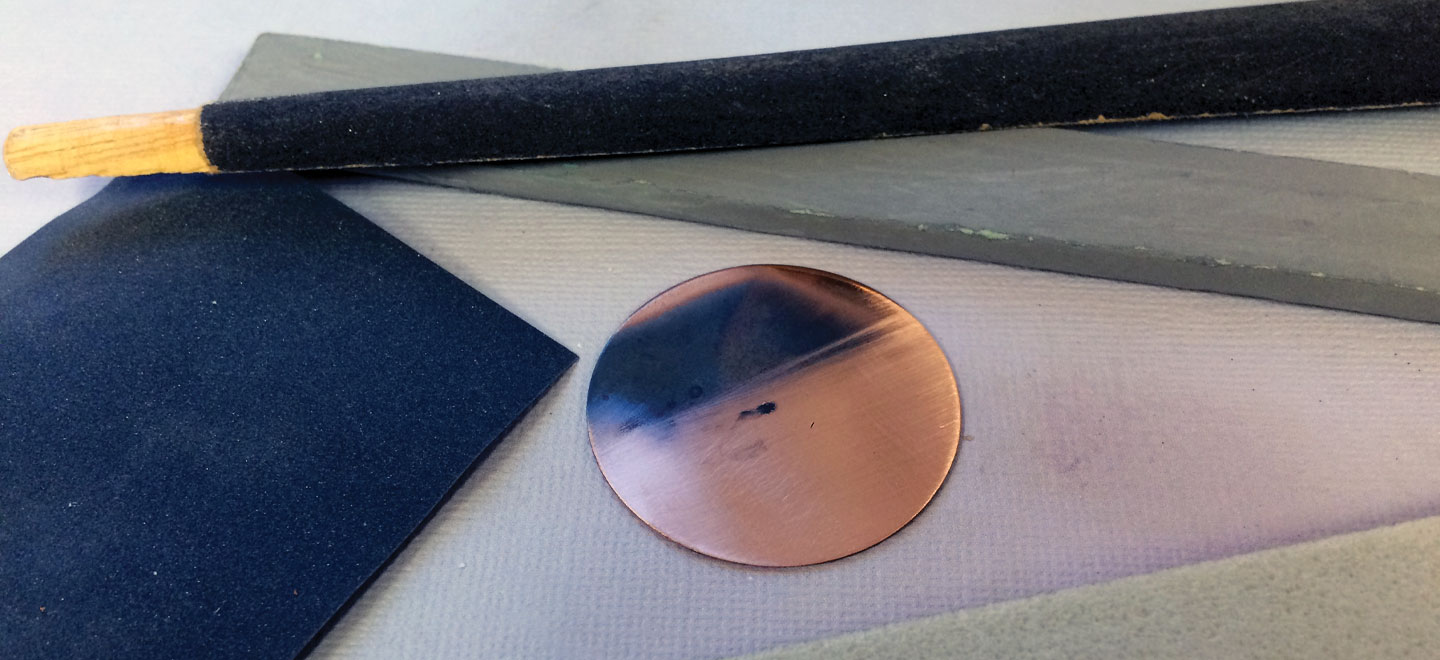

Sandpaper can be purchased from your local hardware store – you do not need ‘jewelry specific’ sandpaper – it’s all the same! Many papers can be used wet or dry, which can help keep down metal dust in the air. One thing I love about sandpaper is that it’s flexible. I’ll create sanding sticks out of 240, 320, 400, and 600 grit sandpapers. Sanding sticks are sandpaper that has been wrapped around a paint stick, flat piece of wood, popsicle stick, etc., and used like a file. Additionally, you can wrap sandpaper around wooden dowels or chopsticks for sanding rounded areas. You can also purchase sanding sticks instead of making your own. The grits above are the ones I use most in the studio, but you can make them out of whatever grits you’d like!

Polishing Papers

Polishing papers are the next step after sandpapers. They are finer and can bring your work to a high polish. Polishing papers are measured in microns. The number measure for microns is different from sandpaper – the higher the number, the more coarse it is. These are great for refinishing the surface of your work or removing patina to highlight certain areas without introducing new scratches.

Sanding sponges are made of foam that has an abrasive bonded to the surface. They are masured the same way and sandpapers, and work in the same way as well. These are also one of my favorite methods for removing patinas because then folded, they kind of float across the surface.

Sanding Tip: Place thin strips of sandpaper or polishing paper in your saw frame for polishing tight places and inside pierced details.

Bench-Top Polisher

Bench-top polishers are a great tool to have in your studio. They can expedite certain processes and, I’ve found, produce the best high polish out there. They come in a variety of sizes, from small, like the one we have in the Halstead studio, to stand-alone larger models. They have two spindles where wheels attach, making it easy to swap out wheels for different sanding and polishing needs. There are a variety of wheels and polishing compounds to use.

Safety is really important when using a polishing machine. You always want to have safety glasses and a mask on, as pieces can catch easily and fly out. If possible, have ventilation hooked directly up to your machine. This will do the bulk of the work, but it’s always a good idea to have a mask on as well. Never have long hair, sweatshirt strings, or jewelry hanging when using this machine. You will always want to work on the bottom quarter of the wheel. This way, if the piece does catch, it will shoot into the back of the machine, and not at your face. Pieces can get quite hot when using a polishing machine, but never wear gloves to protect your fingers from the heat. They are a safety hazard and can get caught easily, bringing your fingers with them. Many people will use rubber finger guards, as they are tight to your fingers and extra grippy.

Polishing Machine Accessories

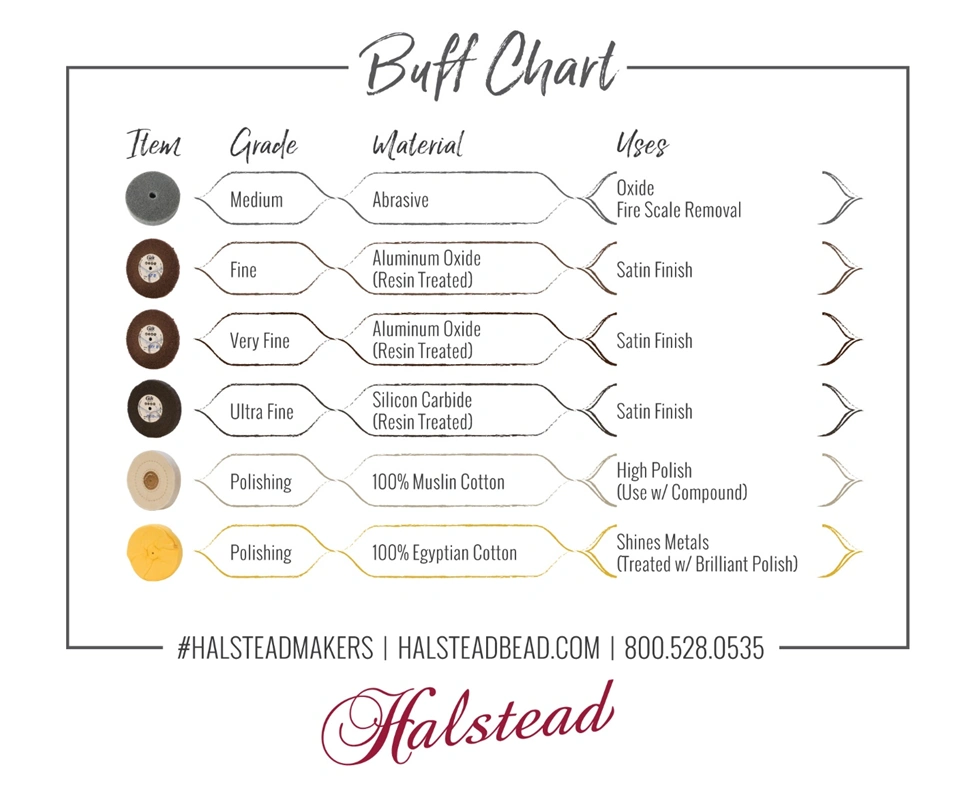

There are so many different wheels to use on your polishing machine. They range from coarser wheels that will take off material or leave a satin finish, to polishing wheels with various compounds, to specialty wheels that will leave a unique texture. Take some time with your favorite tool supplier’s catalogue or website to learn about all of the options.

Your muslin and cotton buffs will need to be used with a compound and are for bringing pieces to a high polish. Some common compounds are Zip, rouge, and Tripoli. It is VERY important to label your wheels with what compounds you’re using as to not contaminate them. They all have different abrasive levels, and you don’t want to mix them. The first time you use a cotton buff, you’ll want to use scissors to trim flyaway fiber strands so it’s nice and smooth. Those can easily get caught in your piece. Our video below goes into setting up our bench-top polisher, and some of our favorite wheels to use.

Tumbler

A jewelry tumbler is another very versatile tool when it comes to cleaning, finishing, and polishing your jewelry. The basics of a tumbler are a barrel where you place your jewelry, a tumbling medium, and water. The barrel then spins, having the medium bump up against your jewelry, for a as long as you’d like. There are all different kinds of tumbling medium for different desired outcomes. Some are more abrasive, like ceramic mediums, and others create a polished, shiny surface, like steel shot or crushed walnut shells. There are other types of tumblers, like vibratory or magnetic tumblers, that work a little differently and have applications they are better for.

Steel shot is one of the most common mediums used in a tumbler. It helps create a high polish finish on your work. When filling your tumbler, it’s important to make sure water completely covers your shot and jewelry. You will also want to add a few drops of a burnishing compound for extra shine. This can be specific to a tumbler, or dawn dish soap! Many will also tumble pieces with steel shot to help work-harden them. It will never do as much as hammering, bending, or twisting, but it can help case harden, or harden the outside layer of metal, for added durability. Watch our video below to see tumbler set up!

Flex Shaft

You already know your flex shaft is an incredibly versatile tool. Whether it’s drilling, stone setting, or polishing – it’s hard to go without! There are a plethora of attachments for finishing and polishing that are made specifically for your flex shaft. They range from highly abrasive to mirror finish polish. Below are a few examples of commonly used attachments for finishing and polishing.

|

Sanding Discs These sanding discs snap on to mandrels and come in a variety of grits from coarse to extra fine. You can also find them with surfaces that are geared towards polishing. These work great when you need an aggressive abrasive. |

|

Radial Bristle Discs You will stack 3-5 discs on one mandrel. They come in a variety of abrasive levels as well, all the way down to 1 micron. They give a great all-over finish. I like the white ones for a satin finish. |

|

Felt Bobs Felt wheels are used for polishing and need to be used with a compound. You can use the same compounds on these that you would with wheels for your bench-top polisher. Make sure not to cross-contaminate compounds. |

|

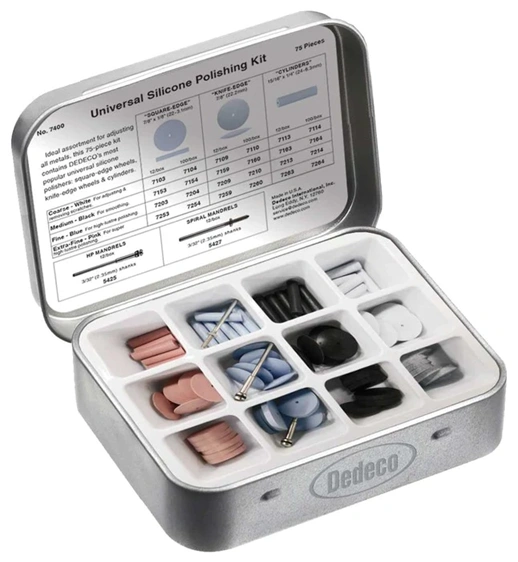

Silicone Wheels Silicone wheels come in a range of grits, from coarse to high polish. Each grit corresponds to how coarse the wheel is. They come in different shapes and sizes as well that allow you to get into tight spaces or create flat edges. Each company will have different colors that corresponds to different grits. |

|

Heatless Wheels Sometimes referred to as ‘mizzy wheels’, heatless silicone carbide wheels are VERY aggressive and take away a lot of material, fast. They’re excellent for removing sprues from castings. |

By no means is the list above exhaustive, or comprehensive. There are SO many options out there! The list above gives you a wide range of uses and finishes, and are all easy to source from your favorite jewelry supplies. Get creative and experiment with different wheels to see what you like best. Have a jewelry friend? Check out their studio and try some of their favorites out. It’s a good way to test wheels without having to purchase. You can check out the video below for a few more options and what to use them for.

Further Reading

What is a Flex Shaft – Why Jeweler’s Can’t Work Without This Tool