Many jewelers remember falling in love with metalsmithing at their first torch soldering experience. That mercurial silver flash when solder starts to flow is magical. But, what is actually happening at that moment? What is the science behind soldering?

While researching for this article on silver jewelry solder, I was surprised by how much I learned. I did not know much about the science behind soldering and it was fascinating to learn about the process in more depth.

Soldering joins two or more metal surfaces by using a compatible alloy that flows at a lower melting point and creates a permanent bond. It's important that the solder flows at a lower temperature so your metal surfaces will remain solid and hold their form. As you heat the material, the atoms that form the metal start to separate. This separation allows the solder, when it flows, to enter those spaces and bond to the original material. The solder has now created a tight fit with the material and the pieces are bonded.

Having now learned the science behind soldering and how the metals intermingle, I, of course, had other questions. What are the metal alloys in solder? Why are those metal alloys chosen? What makes the solder flow faster than the material it's bonding to? So after hours of researching my questions, let's see if I can answer them here.

Understand Your Material

Sterling Silver Sheet

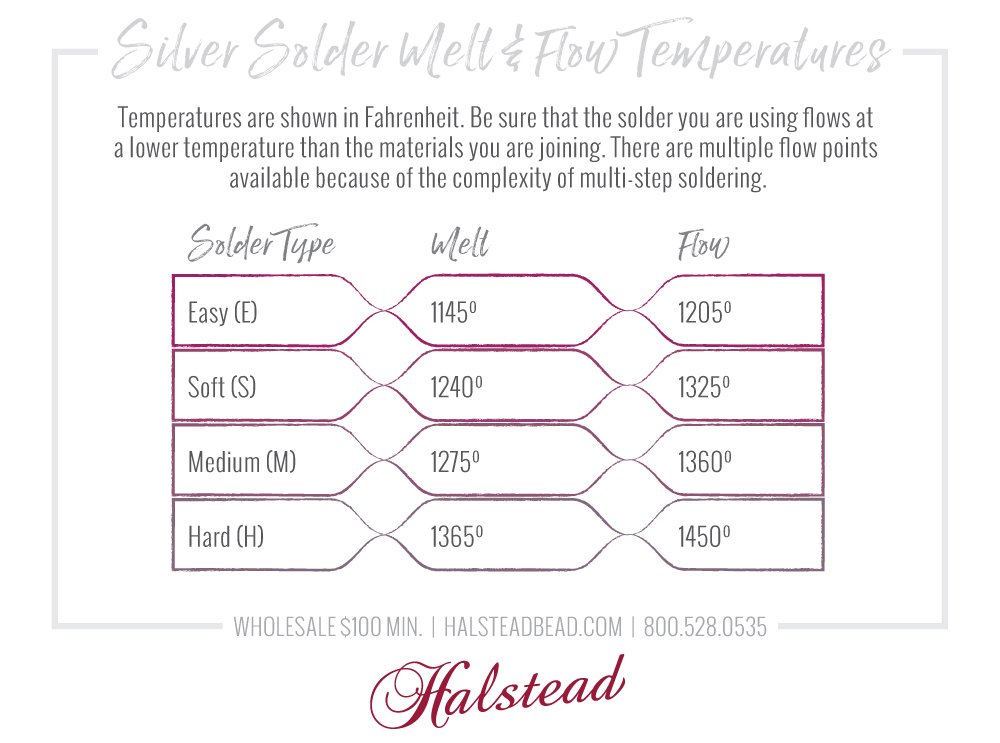

Know the ins-and-outs of the material you're working with. It's important when applying solder, that the melting point of the solder is lower than the metal you are working with. If you were applying solder to a metal in your piece that melted quickly, your piece would become ruined before the solder had a chance to flow. For instance, pewter melts at about 500 degrees F, but easy silver solder doesn't melt until it reaches 1145 degrees F. So if you wanted to solder two pieces of pewter together and used easy silver solder, the pewter would be a melted mess but the silver solder wouldn't be even close to flowing yet.

Note: It's always important to check the melt and flow points between your material and the solder; it could vary between vendors and solders. The words Easy, Medium and Hard are not standardized to fixed temperatures.

Silver Solder Alloys

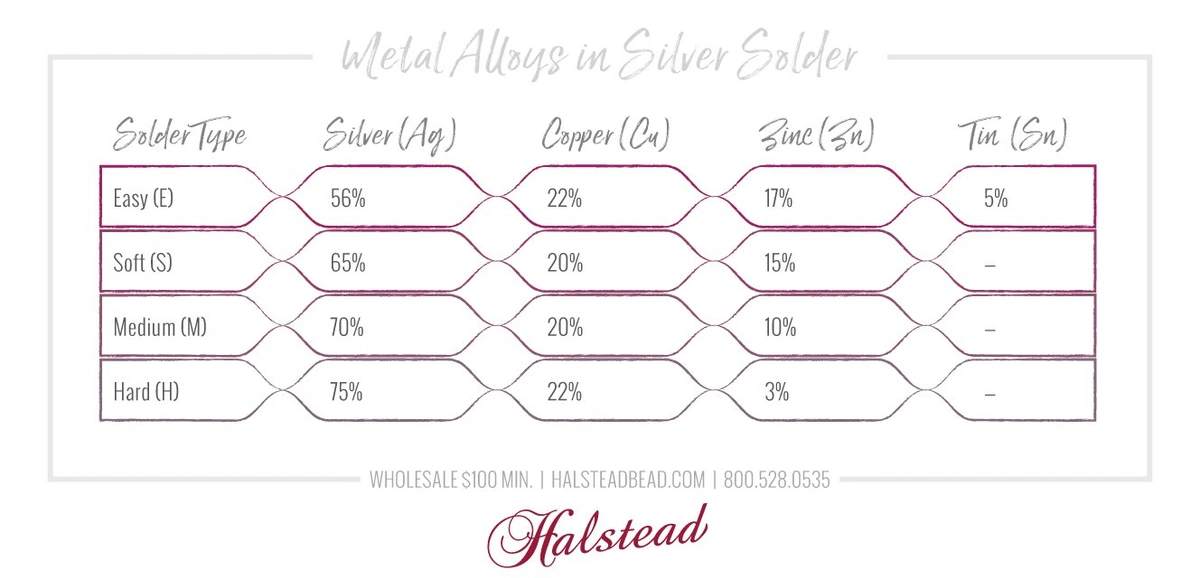

Silver solder has other metals, besides silver, alloyed into it. The alloy is primarily silver but the additional metals provide sought-after characteristics for the purpose of bonding. Copper (Cu) is soft and a great heat conductor plus it's resistant to corrosion. Zinc (Zn) and tin (Sn) have really low melting points, which lowers the overall melting point of the solder. All the silver solders sold at Halstead are lead and cadmium-free. You can find out more of the specifics by reading the SDS sheets on item detail pages on our website, however, the majority of silver solders have a combination of silver, copper, and zinc and the percentage of each metal varies depending on the solder flow point. The solder metal alloys and general percentages are listed in the chart below.

Silver Solder Melting Point

In the chart below, you will find the melt and flow points. As I stated earlier in understanding your materials, you must always be sure that the solder you are using flows at a lower temperature than the materials you are joining. When working with silver, the melting point for .999 fine silver is 1761 degrees F and with sterling silver, it is 1640 degrees F. With solder, there are multiple flow points available because of the complexity of multi-step soldering.

Multi-step Soldering

A multi-step soldering piece requires you to solder different joins without having previous solders re-flow. So, your first solder join would be done using hard solder with the highest melting point, the next join would be completed using medium with a slightly lower flow point so the first join does not come apart and so on. It is important to carefully think through your fabrication plan.

Multi-step Soldering Techniques

While I was in school, one of our assignments was to create a lidded vessel. The lidded vessel below had 13 solder joins! Tackle a multi-step soldering piece like a puzzle, you have to have a well-thought-out design in advance. Then, figure out all of the individual solder joins, decide when and how to use each solder without reflowing a previous join.

Since there are not 13 different flow points available, I had to problem-solve to join several seams at the same melting temp with each heat application. The first solder must be hard with a high flow point, that way when you use medium solder next, it will flow at a lower temperature than the hard solder leaving those joins intact. What about soft and easy solders? Figuring it out was a challenge as a beginner, but worth it to learn this important lesson.

Brazing vs. Soldering

Technically, anything flowing under 800 degrees F is called soldering, anything over 800 degrees F is called brazing. Yep, we're technically brazing and not soldering, folks. In fact, I don't believe I've ever "soldered" in my life. However, the lingo in the field is "soldering," so we'll stick with that convention.

Forms of Silver Solder

Solder comes in 5 basic forms: pallion chips, paste, wire, sheet, and powder. I've tried four of these, unfortunately, the opportunity to try the powder form hasn't come up yet because it is fairly uncommon in jewelry applications. But here's information about each option and their best applications.

Pallion chips: Pallion chips are tiny clipped pieces of solder alloy that can be easily moved with a solder pick. Exact size varies but these are often just 1x1 millimeters or even smaller! I was disappointed when I first tried pallion chips because I used them on a piece that needed more solder than the chips provided. My first reaction was wrong; now, I wouldn't use anything else on chain links, jump rings or small soldering ornaments. I quickly learned with experience that the trick is to add more chips along a join if you need more solder. The small size of chips means you can easily scale the amount of solder you need in very small increments. When working on smaller joins, Pallion chips are a must! SHOP SOLDER CHIPS >>

Paste: This comes in a syringe and is a mixture of flux, binder, and powdered solder. The shelf life on paste is about one year. My experience with paste is that it bubbles, pops and is porous after it flows, plus I'm not crazy about the limited shelf life. The part that I can see as an appeal to others would be that the flux is mixed in so that's one less step. It is also clean and portable if you are creating work outside of your studio on a regular basis. Also, if you use it for closing jump rings and links it can really speed up production work. What about using it with a filigree piece? I personally have never done a filigree piece but a peer in the Orchid Community swears by it. SHOP SILVER SOLDER PASTE >>

"While paste solder may not be the best type of solder to use when sizing rings or fabricating from sheet, it is excellent for hand fabricating filigree jewelry. My primary focus is filigree and I use a lot of paste solder. I also use it to attach findings ie. ear posts, jump rings, etc to my filigree pieces. The joints are strong and do not fail".~ Milt Fischbein

Wire: My go-to solder form. I love using wire solder the most. It can stay in wire form or be clipped and flattened with a hammer, or it can be short or long depending on the work you're doing. It has more versatility than the others so this form is my favorite. A short segment of wire solder goes a long way. It's also easy to pigtail wire solder with different loops to signify the flow temperature points. That way you never have to worry about mixing up your solders! SHOP WIRE SOLDER >>

Sheet: Sheet solder is ideal for large-scale projects where you need a large area joined, such as sculptural pieces or vessels. It's versatile just like wire solder and is easy to use, especially when sweat soldering two flat pieces together. It's easy to use too much when you are trimming from sheet solder, so remember that less is usually better so you don't have too much clean up work.

Powdered: Powdered solder is created by filing solder ingots. You can use it either with a liquid flux or borax and I've heard that it works well for intricate joins.

How to Solder Jewelry

As you progress in soldering, you'll learn different techniques. Each one has its usefulness, depending on the job at hand. Below are the four common techniques used while soldering:

Standard soldering - This is the most common method of soldering. You lay your solder (chip, wire, sheet or paste form) over the join and heat with a torch either from the top or underneath.

Pick soldering - This keeps a lot of heat off of your piece until the end. I like this method when doing fragile work such as chain links, pattern wire and hard to reach areas. Lay a piece of solder on your soldering board, heat it until it rolls into a ball and then pick it up with your soldering pick. Keeping your heat on the ball of solder, move it to the join and then hold it there at the end of the pick until it flows right where you need it to go.

Sweat soldering - If you're soldering two pieces together, this is a great way to control your solder flow. Place one piece upside down on your soldering board. Lay solder down on it, then heat it until the solder melts, then remove the heat immediately (you want to find that spot where the solder melts but has not reached the point of flowing). Flip the piece over onto the other one, solder side between the two. Heat from the top or underneath until the solder flows, making sure to heat the entire piece you want it soldered to.

Stick soldering - Keeping your wire solder uncut, heat the end of the wire and let the solder flow while moving the wire stick around to the areas that need soldering. This soldering technique requires a precise flame, otherwise, you will end up using far more solder than needed.

Tips for Choosing the Right Solder for the Job

Tip: Anytime you fix a visible repair seam try to use the harder solder because the higher silver content can make all the difference between an invisible seam or a tarnished one.

a Finger Ring

You have two choices to make:

- Flow temperature

- Solder form: chips, paste, wire or sheet

Correction Fluid

First, when choosing flow temperature, don't automatically choose the easy and soft flow temperature solders, those actually may be worse in the long run. If you have a visible seam the more silver content in the solder the better. So choose the hard solder (75% silver content) rather than a softer solder with lower silver content. This will slow down the tarnishing on that seam. This tip is more crucial on visible seams.

Having said that, if you have multiple seams on a piece, to prevent the previous joins from re-flowing, use correction fluid or another means of blocking the solder. Yes, there are clean-up steps that you need to take, but I would rather have a longer-lasting seam, and less tarnish, than the few extra minutes it takes to wipe on and clean off a little white-out.

Note: When using liquid correction fluid, be sure that you have proper ventilation and that you wear a mask. The fumes can be toxic.

Earring Post

When doing tiny findings, such as finer gauge jump rings, chain links or earring posts, use soft solder. Otherwise, it's easy to melt your material right along with the solder. The seams on objects this size are barely noticeable and the findings themselves can't take a lot of heat, so get in and out as quickly as possible.

Second, choose the right solder type for the job. Don't use a long piece of solder wire on a jump ring when you can use one tiny pallion chip. As a beginner, I know because I did this, you tend to use far too much solder. I used to flood pieces and then work twice as hard cleaning and finishing than I ever needed to.

Many jewelers stick mostly to one form as their "go-to," but it can be useful to have different options available in the studio.

Watch this video on how to choose the right silver solder.

Federal Trade Commission Rules

Legally, in the United States, in order to call a piece sterling silver, the alloy has to meet the specifications below:

- Sterling Silver = .925 (92.5% silver)

Time and time again, I see inquiries about sterling silver soldered items. Jewelers new to the field worry about the purity of the silver after soldering. The FTC established rules regarding minor variances between batches of manufactured materials. Here are the tolerances for sterling silver based on the National Stamping Act:

Sterling Silver

- .921 = Unsoldered Items

- .915 = Soldered items

As you can see in the solder alloy chart above, silver solder has quite a bit of silver in it. It is unlikely to lower the silver content of an entire jewelry piece enough to fall below the legal requirements because of the alloyed metals in a small solder join. The only time I would worry about it is if I did a fine silver filigree piece with many joins or an intensely granulated design with solder over an entire surface. Here is what Milt Fischbein said about filigree work and soldering:

"My filigree wire is always fine silver and my filigree frames are always sterling silver. Paste solder that I use is about 65% silver. I use as little paste as possible, so it doesn't depress the silver content much. A typical pendant might be about half sterling and half fine silver, although this varies quite a bit depending on the design. Taking it a bit further, if a final piece contained as much as 5% solder, and 45% fine and 50% sterling, it would assay at 94.5% silver. So I always mark my filigree 925. as it should always assay higher and is very unlikely to assay lower." - Milt Fischbein

If you are concerned about a piece, you can always send it off to a lab for testing, that way you can be certain of the results. However, lab tests are destructive so you would need to sacrifice a sample. This is only practical if you are designing a production piece that you intend to produce in quantities.

About Milt Fischbein

Milt Fischbein has been creating jewelry for about 25 years now. He has a Bachelor's degree in Chemical Engineering from McGill University, but 6 years ago he began to focus on fabricating filigree jewelry. You can read his full bio and CV on his website: mfmetalarts, where you can also find his filigree jewelry, tiaras, and crowns. He has taken dozens of courses with teachers such as Alan Revere, Michael David Sturlin, Gerry Lewy and Charles Lewton Brain.

Get Inspired!

Article: Tips for chain End Finishing

Article: 6 Steps to Soldering Earring Posts

YouTube Video: Sweat Soldering 14kt Gold to Sterling Silver (sweat soldering video demo)

Article: Fancy Jewelry Wires: Shaping & Soldering Wire Links (includes a pick soldering video demo)

References:

McCreight, T. (2004). Complete Metalsmith. Brunswick, Maine: Brynmorgen Press, Inc.

Revere, A. (2011). Professional Jewelry Making. Brunswick, Maine: Brynmorgen Press

Got questions? Email us at [email protected]. We’d love to hear from you. Sorry, studio support is not available by phone. Emails only, please.